A field constantly seeing massive new developments, 3D printing, hasn’t been given much national recognition.

Already this year, 3D printing has allowed for the invention of a microscope that attaches to a smartphone to aid in diagnosing cancer in the field, a method of attaching 3D printed objects to one another has been discovered (previously it was thought impossible to change an object’s shape after printing) and a patent was filed for 3D printed rocket fuel, for use in a spacecraft due to take off in 2019.

So, with all these incredible advancements, will 3D printers one day become a regular staple of everyday life?

The first 3D printer was made in 1984, back when technology was unimaginably different than today. While other inventions such as smartphones and the Internet have massively taken off in this time, becoming essentials for people all over the world, 3D printing remains a specialized field — most people in the world have never used a 3D printer themselves. This may suggest that it will never become as widespread as other tech advancements, but I’m not so sure that’s true.

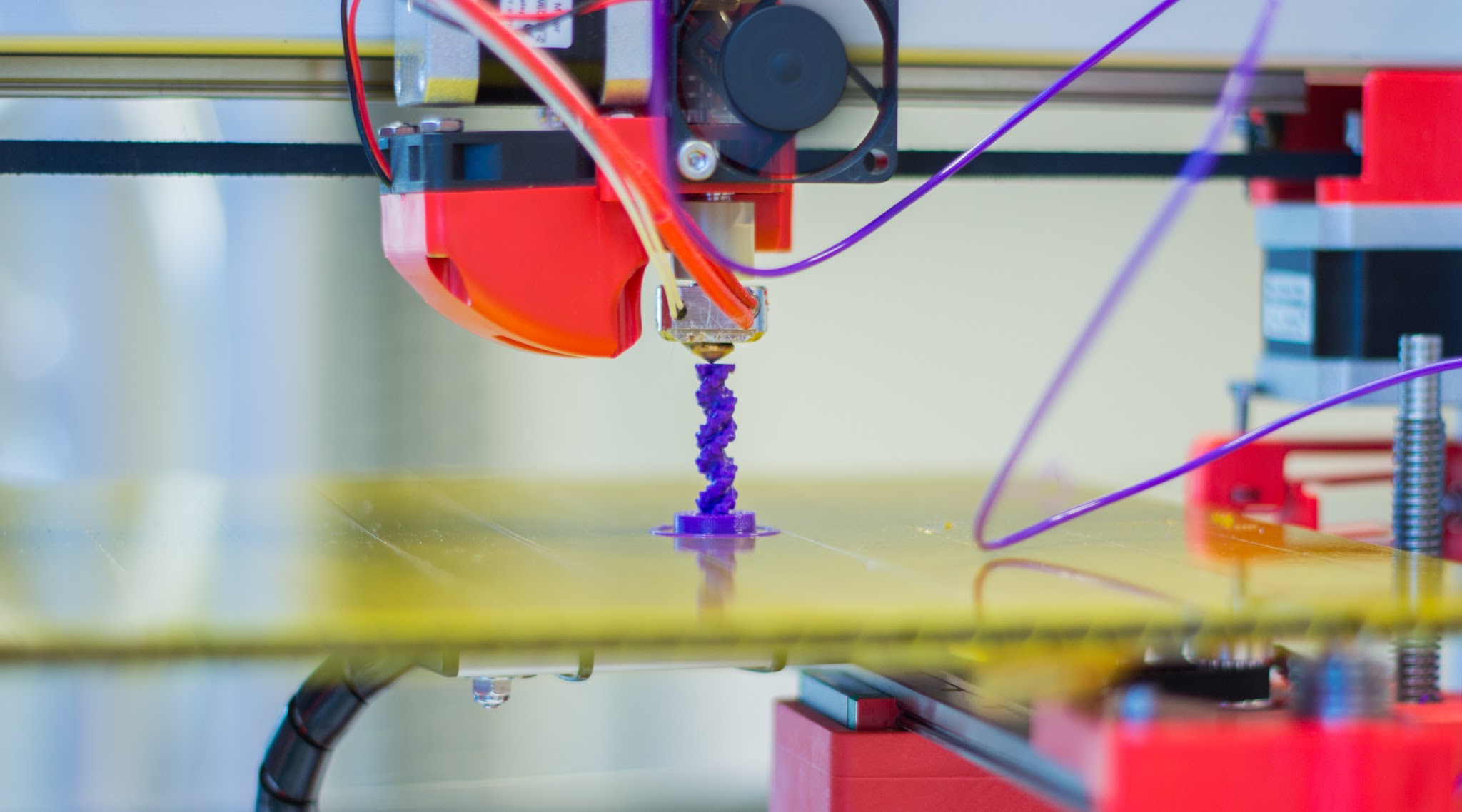

A 3D printer converts a 3D image file into hundreds of 2D images, which, when stacked layer by layer, give the final shape. Each layer of the image is then created sequentially out of the material of choice, with the layers building on top of the previous structure and exposed to heat or ultraviolet light so that it reacts with the previous layer and forms a continuous structure. In the early days of 3D printing, the only materials used were polymers (plastics), as these readily form very long chains of molecules. However, it is now possible to 3D print using metals, fabrics or even pizza.

Since the capabilities of 3D printing are still being investigated and new scientific inventions are constantly being developed due to these machines, scientists and engineers seem to be focusing on pushing the boundaries of these printers and discovering exactly how much they are capable of. Reducing costs and providing basic, cheap versions for average households hasn’t yet been a priority for manufacturers.

But even if 3D printers were affordable, using them isn’t as easy as just hitting “Print” on a Microsoft Word document. These kinds of printers require special software, which isn’t easy to work without lots of practice and graphic design skills, and most people our generation and older just don’t have the time to learn how to use something so complicated.

However, the same can be said of Facebook for our parents and grandparents, and yet that’s become an intuitive skill, so perhaps future generations will play around on 3D design software the same way we played on Microsoft Paint.

While not everything can or should be 3D printed, I think that once scientists turn their attention to making these machines cheaply and readily available to the public, we’ll see a massive increase in the amount of 3D printing in everyday life. After all, there’s so many tempting possibilities — imagine not having any cute shoes to wear on a date and then just being able to print yourself out a custom designed new pair.

That’s the dream.